Roof Underlayment 101: A Roofer’s Perspective for the DMV Area

Key Highlights

- Roof underlayment is a critical layer of protection installed between your roof deck and the final roofing material.

- In the DMV area, underlayment provides essential defense against our varied weather, from heavy rain to high winds to occasional heavy snowfall.

- Key types include traditional asphalt-saturated felt, modern synthetic options, and self-adhered membranes – Ice and water.

- Choosing the right underlayment extends the life of your entire roof system.

- A professional roofer ensures proper installation for a watertight seal in the most vulnerable areas of your roof.

Introduction

When you think about your roof, you probably picture the shingles, cedar shake, metal, slate, or Spanish tiles. But one of the most important parts of your entire roof system is the one you can’t see. We’re talking about roofing underlayment, the hidden shield that provides a crucial secondary defense for your home. Without it, your roof is vulnerable to water damage and premature aging. As your local DMV roofer, we believe every homeowner should understand what’s truly protecting their home from the elements and why investing in better quality will give you peace of mind for years to come.

Roof Underlayment Explained: The Essentials for Our Local DMV Homes

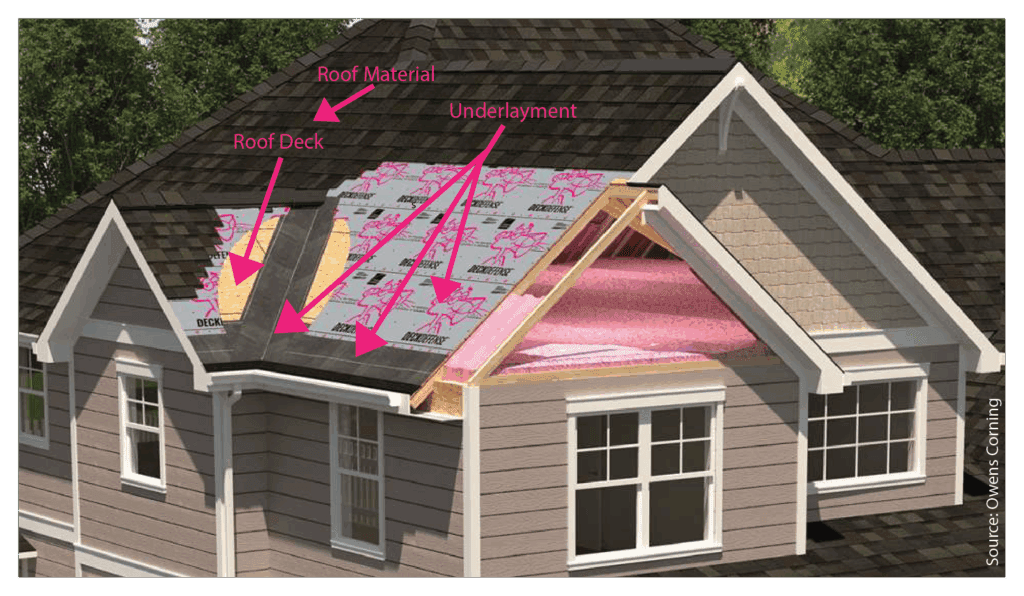

So, what is roof underlayment, and why is it important for protecting a home? Simply put, roof underlayment is a water-resistant or waterproof protective barrier. A roofer installs this material directly onto your roof deck before the final roofing material, like shingles, is put in their place.

In the DMV region, with our unique mix of heavy rain, snow, and humidity, this layer isn’t just a bonus—it’s essential. It acts as a backup shield, ensuring that even if wind drives rain seeps under your shingles, your home’s structure stays dry and secure.

What Is Roof Underlayment Anyway?

During a roofing project, the underlayment is one of the first materials to go down. It is a secondary layer installed directly on top of the roof deck, which is the wooden sheathing (such as step sheathing, Plywood, or OSB) that forms the base of your roof. This material, sometimes referred to as “roofing felt” or “tar paper”, sits just beneath your final roof material. (As depicted in the roof cutaway image above)

Its main purpose is to be the second line of defense within your comprehensive roof system. While your roof material (shingles, etc.) is the primary barrier, they aren’t foolproof. During severe storms with wind-driven rain, water can sometimes find its way past the shingles. The roof underlayment is there to catch this water, preventing it from soaking into the wood and causing damage to your home’s interior.

There are several types of underlayment available, each offering different levels of protection and durability. From traditional felt to advanced synthetic, as well as insulated options. A quality roofing company has a range of materials to choose from to create a robust layer of protection tailored to your home and climate.

Why Is Roof Underlayment Crucial for Home Protection?

Ignoring the underlayment is a mistake that can lead to significant and expensive water damage. It serves as a vital protective barrier, safeguarding the wooden roof sheathing from moisture that could otherwise lead to rot, mold, and serious structural issues.

This water-resistant layer is critical for several reasons. It provides:

- A secondary shield: It stops water infiltration in case a shingle is cracked, damaged, or blown off in a storm.

- Protection for the deck: It shields the roof sheathing from moisture, which can cause rot and decay over time.

- A barrier during installation: It protects the exposed roof deck from the elements before the final roof material is installed.

Ultimately, a quality underlayment can double the effective lifespan of your roof. The durability and performance are affected by factors like material quality, thickness, and proper installation. Without it, your roof is far more vulnerable, and you significantly increase the chances of leaks and costly repairs down the line.

Key Functions of Roof Underlayment

Not only does roof underlayment add a vital protective layer to your roof, shielding your home from weather and moisture damage. It’s essential for preventing long-term structural issues. Some types also boost energy efficiency by providing extra insulation, helping regulate temperature, and lowering heating and cooling costs. We’ll explore its roles as a moisture barrier and secondary defense in more detail.

Moisture and Water Barrier

Roof underlayment acts as a moisture barrier, preventing wind-driven rain and melting snow from reaching your roof’s wooden deck. Even with well-installed shingles, underlayment is crucial to avoid water damage, mold growth, rotted wood, and ruined insulation—especially in wet climates.

For areas with heavy rain and snow, waterproof options like premium self-adhered membranes (often rubberized asphalt) provide a fully sealed layer. Roofers install these in vulnerable spots for maximum leak protection.

Secondary Defense Against Leaks and Storms

Think of your roof underlayment as your home’s backup plan during extreme weather. If high winds tear off a shingle or hail causes a crack, the underlayment is the secondary defense that kicks in to prevent immediate leaks. It’s your roof’s insurance policy against the unexpected.

This backup protection is especially important in several key scenarios:

- During high winds – It protects the roof deck if shingles are lifted or blown away.

- Around vulnerable spots – It helps seal around roof penetrations like vents and chimneys, which are common sources of leaks.

- Ensuring proper drainage – It helps channel water correctly off the complex angles of roof planes, preventing it from pooling.

The durability and performance of the underlayment are key here. Materials with high tear resistance and the ability to self-seal around fasteners are less likely to fail under stress, reducing the risk of leaks and giving you peace of mind during the next big storm.

Main Types of Roof Underlayment Available

There are three main types of roof underlayment: asphalt-saturated felt, synthetic underlayment, and self-adhered membranes. Each varies in cost, durability, and protection. Your best option depends on your budget, roofing material, and required level of protection.

Traditional Asphalt-Saturated Felt

For decades, asphalt-saturated felt was the standard choice for roofers. This felt underlayment, also commonly called “tar paper” or “felt paper”, is made by saturating a base material of organic or fiberglass fibers with asphalt. It provides a basic level of water resistance and is the most affordable option.

This asphalt underlayment is still used today, particularly on projects with tight budgets or on steeper roofs where water runs off quickly. Here is a quick breakdown of the pros and cons:

| Feature | Description |

|---|---|

| Material | A base mat of organic or fiberglass fibers saturated with asphalt. |

| Pros | Highly affordable and widely available. |

| Cons | Heavy material to transport, can tear easily during installation, can absorb moisture, and wrinkle or degrade over time. |

| Best For | Steep-slope roofs and budget-focused projects. |

Synthetic Roof Underlayment

Synthetic roof underlayment, made from woven polymers like polypropylene or polyethylene, is the top choice for modern roofing. It’s stronger, lighter, and easier to install than traditional felt.

Advantages of Synthetic underlayment:

- Resists tears, water absorption, and UV damage

- It’s lightweight design with more coverage per roll. This will reduce the number of trips up and down the ladder, resulting in lower labor costs.

- It repels water and is inert to mold growth.

- Provides a secure walking surface free from wrinkling or warping.

- Typically, it features clear overlapping lines for easy, fault-free installation.

- For durability and longevity, synthetic underlayment is a smart upgrade for homeowners.

Self-Adhered (Peel-and-Stick) Underlayment

For superior leak protection, self-adhered underlayment is a top choice. Made from rubberized asphalt with an adhesive backing, it creates a watertight seal when applied directly to the roof deck.

Its blend of asphalt and rubber polymers keeps it flexible in changing temperatures and allows it to self-seal around nails and staples—something other types can’t match.

This underlayment is ideal for areas with heavy rain and for vulnerable roof sections like low slopes, valleys, eaves, around chimneys, and skylights, as well as edges prone to ice dams.

Choosing the Right Underlayment for Your DMV Roof

So, how do I choose the right type of roof underlayment for my roof? With several options available, making the right decision for your DMV home involves weighing a few important factors. Selecting a quality underlayment is just as important as choosing your shingles.

To ensure your roof is prepared for our local climate, you’ll need to consider the weather, your primary roof material, and local regulations. A professional roofer can help you navigate these choices to find the perfect balance of performance and cost for your specific project.

Considering Local Climate: Rain, Snow & Humidity

The DMV’s climate brings hot, humid summers, intense sun, heavy rain, and winter snow and ice. Your roof underlayment must withstand these extremes year after year.

When choosing underlayment, look for:

- Water Resistance: Handles heavy rain and snow, preventing leaks and ice dams.

- Moisture Protection: Synthetic options resist humidity to prevent mold and rot.

- Temperature Durability: Should not crack in cold or break down under strong UV rays.

Given these conditions, local roofers often recommend synthetic or self-adhered underlayments for superior protection and long-term durability.

Matching Underlayment to Roofing Material

The roofing material you choose determines the best underlayment for your home. Both must be compatible to form a strong, protective roof.

Asphalt shingles work well with most synthetic underlayments. Heavier materials like tile or slate need a durable, tear-resistant underlayment for support. Metal roofs require underlayments with high-temperature ratings to prevent damage.

Your roofer will guide you in selecting an underlayment that matches your roofing material, ensuring both work together for long-lasting performance.

Building Codes and Warranty Requirements

Your choice should be guided by local building codes and manufacturer warranty requirements—rules you must follow for a safe, protected roof.

DMV municipalities set minimum standards for underlayment type and quality. Most shingle manufacturers will void warranties if you use incompatible or improperly installed underlayment; many require their own products.

Hiring a professional roofer ensures your project meets all codes and warranty terms, guaranteeing proper roof performance and protecting your investment.

Conclusion

Roof underlayment is crucial for protecting your home in the DMV area, acting as a barrier against moisture, leaks, and harsh weather. Understanding options like felt, synthetic, and self-adhered underlayment helps you choose what best suits your needs while meeting building codes and warranty requirements. For roof upgrades or new installations, consult a local roofer to select the most effective underlayment and ensure lasting protection.

Frequently Asked Questions

Is Synthetic Roof Underlayment Better Than Traditional Felt?

In most situations, yes. Synthetic roof underlayment offers superior durability, tear resistance, and water protection compared to traditional felt underlayment. While felt is more affordable, a quality underlayment like synthetic provides more reliable and longer-lasting weather protection, making it a better investment for nearly any roofing material.

Can Roof Underlayment Be Installed Over Old Roofing Material?

No, this is highly discouraged. For a proper roof system, underlayment materials must be applied directly to a clean, smooth, and dry roof deck. A professional installation always involves removing old materials to inspect the deck for damage and ensure a watertight seal, which reduces the risk of leaks.

How Long Does Roof Underlayment Typically Last Compared to Shingles?

A proper underlayment is designed to last the entire lifespan of the shingles above it, typically 15 to 30 years. Because it is protected from direct UV exposure by the asphalt shingles, its longevity depends on its material quality. Synthetic options generally have a longer lifespan than traditional felt.

Can I install underlayment over old shingles, or do I need to completely remove the existing roofing material?

When installing roof underlayment, it is generally recommended to remove the old roof surface entirely to ensure proper adhesion and effectiveness. Installing underlayment over an existing roof may compromise its protective qualities, especially against extreme weather conditions.